In the world of manufacturing, efficiency is paramount. One of the biggest hindrances to a smooth manufacturing process is what’s known as a ‘bottleneck’. This term refers to the point in the production line where work accumulates faster than it can be processed. Fortunately, scheduling software has emerged as a powerful tool to address and eliminate these bottlenecks.

Understanding Bottleneck Resources

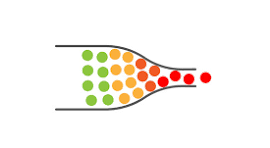

Bottleneck resources are those parts of the production process that limit the overall output. They are essentially the slowest link in your manufacturing chain and have the ability to negatively impact the efficiency of the entire operation. For example, if a factory has a machine that can produce 100 units per hour, but it only has the capacity to package 50 units per hour, the packaging becomes a bottleneck resource. The result is a backlog of products waiting to be packaged, leading to delays and inefficiencies.

Scheduling software can help manage these bottleneck resources by optimizing their use. It can ensure that resources are utilized to their maximum capacity and that there is a balance in the workflow, preventing any accumulation of work at any point in the production line.

The Issue of Bottleneck in Manufacturing

Bottlenecks in manufacturing occur when there’s a disparity between different stages of the production process. This could be due to a variety of reasons such as equipment malfunction, lack of skilled labor, or poor planning. If a particular machine frequently breaks down, it slows down the entire production line. Similarly, if there aren’t enough skilled workers to operate certain machinery, it creates a delay in the process.

The consequences of not addressing these bottlenecks can be severe.

Consequences of Untreated Bottlenecks in Manufacturing

- Missed Deadlines: When production is slowed down due to bottlenecks, it can lead to an inability to meet set deadlines. Products are not ready when expected, resulting in delays that can impact all subsequent stages in the supply chain. Missed deadlines may also lead to a breach of contracts, which could have legal implications.

- Increased Costs: Bottlenecks can result in higher operational costs. Idle time of workers and machinery due to slower processes means money is being spent without any return on investment. Additionally, rush orders or overtime to make up for lost production time can significantly increase cost of production.

- Reduced Quality: In an attempt to speed up production and overcome the bottleneck, there might be a compromise on the quality of the product. Hasty production processes can lead to errors, defects, and a final product that does not meet the company’s usual standards.

- Dissatisfied Customers: The culmination of missed deadlines, higher costs, and reduced quality can lead to dissatisfied customers. Delays in product delivery can turn away customers, increased costs may get passed on to the customer, and lower quality products can damage a company’s reputation, reducing trust and customer loyalty in the long run.

Bottlenecks Exist in Which Type of Manufacturing Processes

Bottlenecks can occur in any type of manufacturing process, whether it’s continuous, job shop, batch, or mass production.

In continuous manufacturing, for instance, bottlenecks can occur if there’s a breakdown in one part of the production line, as the entire process is interconnected. In job shop manufacturing, bottlenecks can occur if there’s a delay in one specific job that holds up other jobs in the queue.

Scheduling software can be tailored to address bottlenecks in different types of manufacturing processes. It can optimize the flow of work in continuous manufacturing, prioritize jobs in job shop manufacturing, and manage the batch sizes in batch production.

How to Eliminate a Bottleneck in Manufacturing

Identifying bottlenecks is the first step towards eliminating them. This involves a thorough analysis of the entire production process to determine where work is accumulating.

Once identified, scheduling software can play a crucial role in eliminating these bottlenecks. The software can help reorganize the workflow, allocate resources more efficiently, and even predict potential bottlenecks before they occur.

For example, if the software identifies that certain machinery often breaks down, it can schedule maintenance during off-peak hours to prevent disruptions. Similarly, it can ensure that skilled labor is evenly distributed across all stages of production to prevent any delays.

A Solution to Bottleneck Problems

Protected Flow Manufacturing is a strategy that prioritizes work based on the constraints in the manufacturing process. It aims to ensure that work flows smoothly through the production line without getting stuck at any point.

Scheduling software plays a vital role in implementing Protected Flow Manufacturing. It uses real-time data to adjust the schedule based on the current state of the production line. This allows it to anticipate and address bottlenecks before they become a problem, ensuring that the flow of work is always protected.

Avert A Bottleneck in Manufacturing

In conclusion, bottlenecks are a common issue in manufacturing that can severely impact efficiency and productivity. However, with the help of scheduling software, manufacturers can identify, address, and even prevent these bottlenecks. By optimizing the use of resources and implementing strategies like Protected Flow Manufacturing, scheduling software is truly revolutionizing the way we approach manufacturing. Contact us to learn more about how our scheduling software can help your business eliminate bottlenecks and improve overall efficiency. Let us help you stay ahead in the competitive manufacturing industry.