Calculating On Time Delivery (OTD): A Critical Metric for Manufacturing and Its Impact on Scheduling

In the competitive landscape of manufacturing, calculating On Time Delivery (OTD) stands as a crucial benchmark that determines a company’s reliability and efficiency in meeting customer demands. As businesses strive to uphold their reputations and ensure customer satisfaction, understanding and improving OTD becomes imperative. This blog delves into the essence of OTD, its calculation, and… READ MORE

Navigating Planning and Scheduling in Manufacturing with Smart Solutions

In the complex world of manufacturing, planning and scheduling in manufacturing are critical components that determine the efficiency, productivity, and profitability of operations. However, manufacturers often face a myriad of scheduling issues, ranging from overlapping production schedules to inefficient resource allocation. These challenges can significantly hamper a company’s ability to meet demand, manage resources effectively,… READ MORE

How Job Shop Scheduling Software Revolutionizes Manufacturing for Small-Medium Businesses

In the competitive landscape of manufacturing, small to medium-sized businesses (SMBs) face unique challenges that can significantly impact their growth and sustainability. These challenges often revolve around optimizing production processes, managing resources efficiently, and meeting customer demands in a timely manner. One technological innovation that is making waves in this sector is job shop scheduling… READ MORE

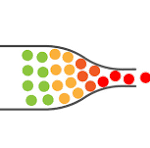

Streamlining Your Factory Floor With Manufacturing Scheduling Software

In the fast-paced world of manufacturing, efficiency and productivity are paramount. The ability to quickly adapt to changes, manage resources effectively, and maintain optimal production levels is what sets successful manufacturers apart. This is where the power of manufacturing scheduling software comes into play, transforming the way factory floors operate and significantly boosting their output.… READ MORE

Create Profitable OTDs with Scheduling Software for Manufacturing

In the fast-paced world of manufacturing, On-Time Deliveries (OTDs) are crucial to maintain a competitive edge. With customers demanding faster and more reliable deliveries, manufacturers are turning to technology to improve their OTD rates. One such technological solution is scheduling software for manufacturing. This powerful tool can significantly enhance manufacturing processes, leading to higher profitability.… READ MORE