The Right Kind of Shop Floor Visibility – Right Now

For manufacturers feeling powerless over shop floor production, Protected Flow Manufacturing™ (PFM) helps you drastically improve on-time delivery by prioritizing what needs to happen first, not what’s due first.

Alert. Recommend. Do.

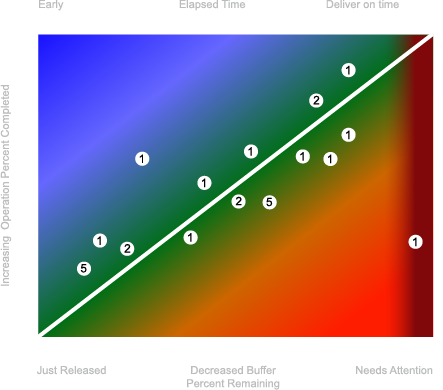

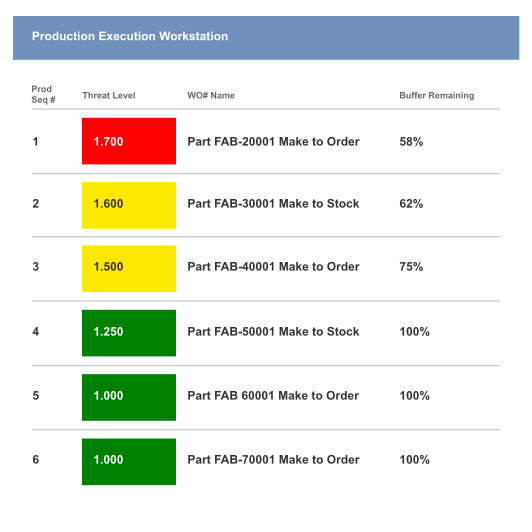

PFM’s Threat-Level Prioritization increases shop floor productivity and promotes better flow by bringing actionable intelligence directly to those closest to the work and ensuring everyone is always working on the right job, next.

- Gain instant visibility into your entire WIP status and each work order’s associated Threat Level.

- Identify work orders at risk of being late and problematic operations that need urgent attention.

- Know exactly where your work orders are and how they’re progressing, which job to work on next, and when customers will receive their order.

There’s Nothing Finite About It

Unlike traditional shop floor production scheduling that focuses on finite capacity and static planning, PFM is the only manufacturing production planning and execution system that accounts for variability by adjusting to real-time conditions.

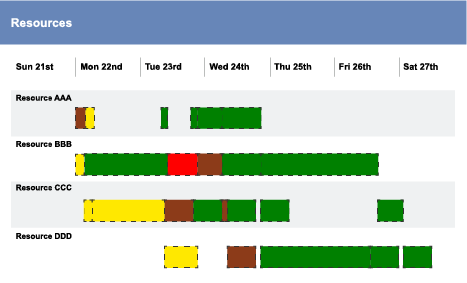

- Prevent resource bottlenecks, increased wait times, and confusion over priorities by controlling the release of work with a “just-right date.”

- Make and keep your customer promises with time allowances that stay up-to-date with the passage of time.

- Eliminate time-consuming production scheduling meetings with a simple, powerful priority method that everyone can agree on.

Prove the Work

Before You Do the Work

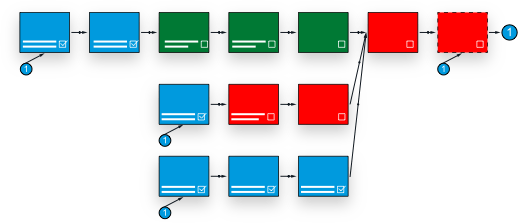

Stop struggling with shop floor production scheduling software that relies on “best-laid plans.” With PFM Planning, simulate the way you’ll be executing jobs at each future moment to identify and prevent problematic work orders from derailing production.

- Expose obstacles such as machine bottlenecks, manpower constraints, and material/tooling availability.

- See how and when you will be able to complete all jobs based on the capacity and resources you have.

- Simulate your future by the week, day, hour, or even minute-by-minute to show issues as they’re predicted to occur.

Easy to Integrate, Easier to Use

PFM is designed to deliver results, fast, and can be customized to work with how you already manage shop floor production today – whether that is as a standalone solution or integrated with your existing manufacturing ERP.

- Accept data from virtually any source, including a standard connector that integrates directly with most manufacturing ERP software.

- Reduce your total cost of ownership with a cost-effective, cloud-based solution that can be accessed anytime, anywhere.

- Get up and running quickly and build trust in PFM with dedicated service and support from a team that is invested in your success.

"Your ERP isn't Helping in Production" And how to fix it!

Manufacturing companies today want is to be able to answer these questions quickly, easily, and visually:

- Customer called, wants to know where her order is, and when she can get it?

- How is any job or even all jobs tracking against when they need to ship?

- What jobs do I need to start today? Do I have material for it? If not, when will I get it?

- I have sub-assembly dependencies. My sub-assemblies even have sub-assemblies. How do I manage the due dates and dependencies on all those workorders?

- I’ve got 4 or 5 jobs waiting to be worked on in any workcenter. How do I know which one to work on next?

- Customer just changed the due date on our biggest order – what will that do to all our other orders?

Watch the 3-part webinar series to learn more on how to unleash your company’s Manufacturing potential today!

Integrations

Let Us Show You a Better Way

Stop struggling with the limitations of traditional shop floor production scheduling. We can help you gain the visibility and control you need to manage shop floor production with confidence and protect customer commitments.

Contact us today to learn how PFM can help:

- Dramatically improve the flow of materials

- Reduce WIP

- Achieve shorter lead times and better on-time delivery

- Increase throughput to your bottom line

Gain actionable intelligence you can trust

Gain actionable intelligence you can trust Prioritize based on how you actually work

Prioritize based on how you actually work Predict a better future for your shop floor

Predict a better future for your shop floor Deliver the results you need – fast

Deliver the results you need – fast 3-part recorded webinar series: Scheduling, Material Planning and Costing

3-part recorded webinar series: Scheduling, Material Planning and Costing