The Keys to Improving On-time Delivery, Customer Satisfaction, and Your Company's Financial Performance.

Attend a live event or view a recent recorded webinar to learn how we can help you gain the visibility and control you need to manage production more efficiently, effortlessly. When you're ready to take the next step, we'll be eager to meet you, learn about your challenges, and discuss how you can quickly take advantage of this focused, data-driven approach to managing production.

Recorded Webinar: Rethink Managing Production - Material Planning

Even the best “schedule” in the world won’t help you if you struggle getting the materials required “On-Time”! Whether raw materials or sub-assemblies, just one missing component, and your schedule is “On-Hold”!

Any ERP that calls itself a “Manufacturing ERP” will have traditional MRP embedded in it. But regardless of how new your ERP is, the underlying functionality of MRP was designed in the 1960’s and ’70’s – and has not changed much since then!

In this Webinar, learn how you can improve your on-time delivery and reduce lead-times by gaining visibility of:

- The right time to start a job,

- Dependencies of make-to-order or make-to-stock subassemblies, and

- Making sure you always have “enough” of any item, without ever having “too much”!

Click “Learn More” to watch the webinar

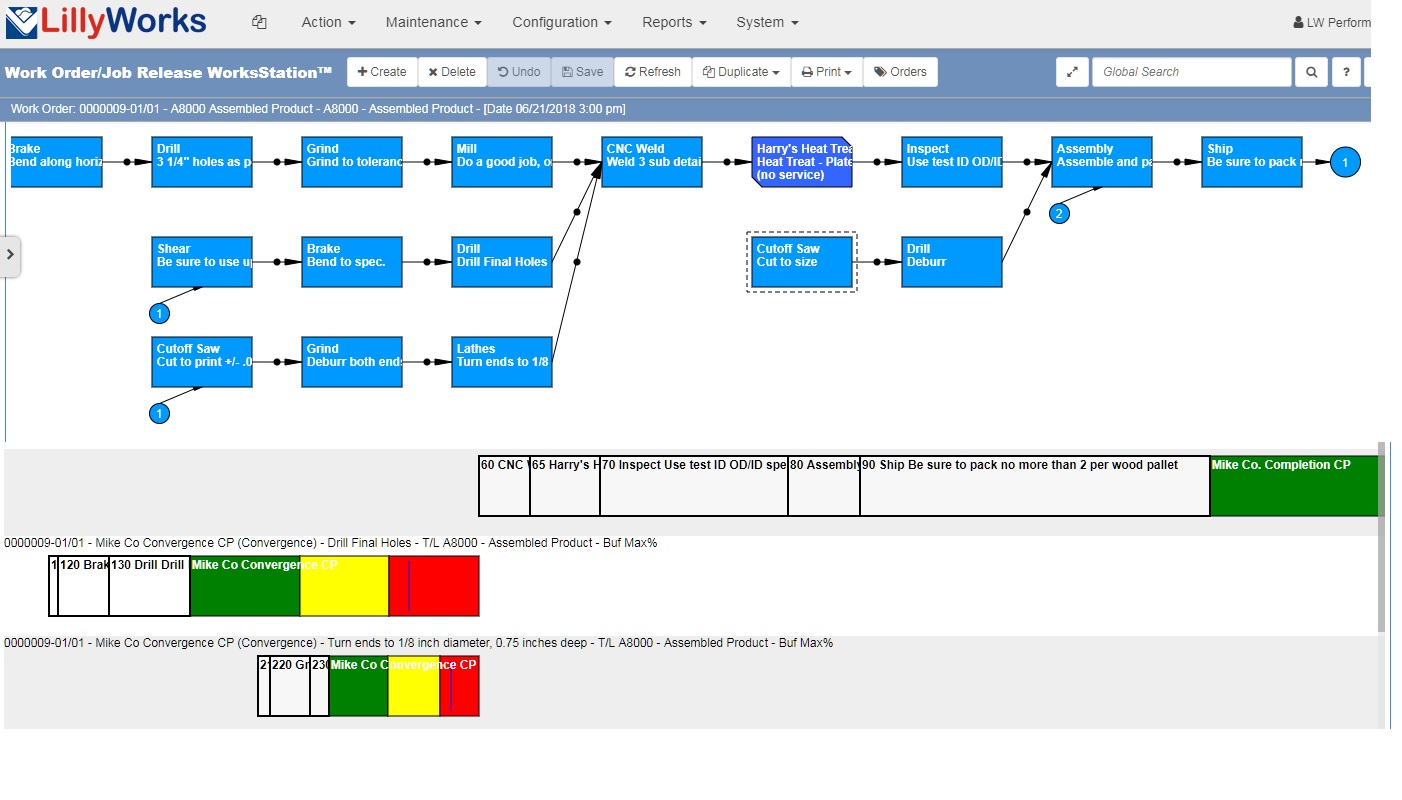

Recorded Webinar: Rethink Managing Production - Scheduling

Manufacturers are really just trying to answer a few simple questions regarding Production Scheduling:

- Where is/are my job(s), how is/are it/they progressing?

- Which job/workorder should I be working on right now – plant-wide or in any specific workcenter/machine/person?

- Given my plants capacity and current/future load (backlog), when will my customer be able to get their order?

Learn why spreadsheets, whiteboards, and even ERP / Advanced Planning and Scheduling (APS) tools are not working for you.

Click “Learn More” to watch the webinar

Recorded Webinar: Why your ERP is not helping you in Production

Most companies have struggled long enough with outdated ERP functionality for production so are ‘managing production’ using manual whiteboards, and spreadsheets.

These are time-consuming and tedious, and don’t provide the visibility needed to be able to quickly and easily answer the questions addressed to Production Management on a daily, even hourly basis.

Learn this how to use this proven approach to address all your Production Management needs and questions using the information you already have in your ERP today.

Click “Learn More” to watch the webinar

Recorded Live Presentation - "Improving On-Time Delivery" - at American Aerospace & Defense Summit

If you’re in the Aerospace & Defense manufacturing supply chain, you know how critical on-time delivery is. Even if you’re not serving A&D type customers, you know the benefits of shorter leadtimes, and being able to quote an accurate delivery date – and live by it.

Learn why spreadsheets, whiteboards, and other traditional ERP-based planning and scheduling tools are not working for you. Then we introduce you to a simple, yet powerful way to greatly improve your On-time delivery by being able to use the data you have today to answer the following fundamental production questions:

- Where is/are my job(s), how is/are it/they progressing?

- Which job/workorder should I be working on right now – plant-wide or in any specific workcenter/machine/person?

- Given my plants capacity and current/future load (backlog), when will my customer be able to get their order?

Click “Learn More” to watch the webinar

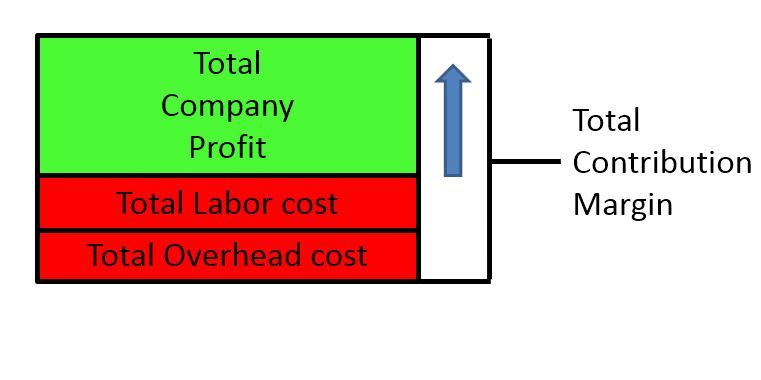

Recorded Webinar: Rethink Managing Production - Costing

In Part 3 of this webinar series on Costing we’ll explore a way to view your manufacturing costs so you can make better decisions to drive performance in the desired direction.

- What are the 4 Manufacturing Cost Categories most use to evaluate cost performance?

- What is the true nature of these manufacturing cost categories?

- How can a new perspective into manufacturing costs provide the ability to make the best decisions for the health of your manufacturing company? Review a number of examples.

Learn why using traditional costing methods can actually provide data that drives decision making in the opposite direction of your intended performance goals. This may aslo be considered an introduction into “Throughput” Accounting. Also known as Contribution Margin Analysis and Value-Added Revenue approaches.

Click “Learn More” to watch the webinar

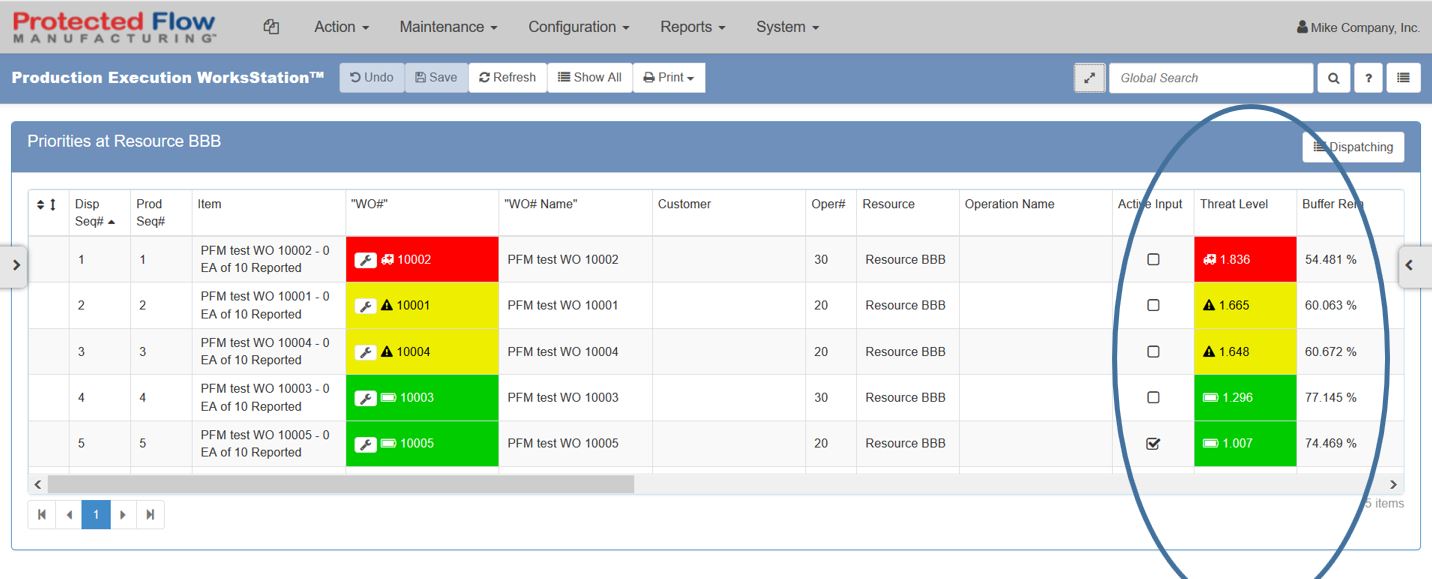

Using Digital Transformation and Predictive Analytics to Solve Production Scheduling

IMTS Spark Conference – Live Recorded Session

Most manufacturers – especially custom, make-to-order, and jobshops – struggle with getting their orders to their customers on-time. In spite of having the latest technology, most ERP’s and APS systems production scheduling functionality is based on the traditional finite capacity planning model from the 1970’s and 80’s – and hasn’t changed much since then.

This session will describe a new approach that uses digital transformation of existing workorder/job information into actionable, real-time, relevant intelligence to drive prioritization of shop floor execution. Then, it will show how Predictive Analytics and computer simulation can be used to show future shop floor capacity loading, identify bottlenecks, and evaluate different ‘what-if’ production scheduling scenarios.