In the fast-paced world of manufacturing, maintaining efficiency and productivity is paramount. This is where manufacturing operations management software plays a vital role. Not only does it streamline processes, but it also ensures that every task is performed optimally, enhancing overall productivity.

Understanding Manufacturing Production Management Software

Before we delve into the specifics, let’s first understand what manufacturing production management software is. Simply put, this type of software is a digital solution that helps manufacturing units effectively manage and optimize their production process. By automating various tasks and streamlining operations, it enables efficient scheduling, inventory management, quality control, and provides detailed analytics and comprehensive reports. With manufacturing production management software, businesses can enhance productivity, minimize errors, and make informed decisions to drive success in their operations.

The Role of Manufacturing Shop Management Software

Manufacturing shop management software is a specific type of software that plays a crucial role in streamlining and optimizing the operations within a manufacturing shop. By effectively coordinating and managing various tasks, this software ensures that all activities are scheduled appropriately and aligned with the overarching business objectives. It acts as a reliable and efficient manager, working tirelessly to enhance productivity and efficiency in the shop. With this software in place, businesses can expect improved organization, better resource allocation, and ultimately, significant growth and success.

Key Features of Manufacturing Operations Management Software

Manufacturing operations management software is packed with features that make managing a manufacturing unit a breeze. Let’s look at some of these features:

Task Scheduling and Tracking

One of the primary features of any manufacturing operations management software is task scheduling and tracking. This feature ensures that every task is scheduled appropriately and tracked from start to completion, eliminating the risk of missing deadlines or overrunning the budget.

Inventory Management

Another critical feature of manufacturing operations management software is inventory management. It allows businesses to keep track of their stock levels and ensure they have enough materials to meet production demands.

Quality Control

Quality control is another crucial aspect that this software handles efficiently. It ensures that every item produced meets the established quality standards, reducing the risk of producing substandard products.

Reporting and Analytics

Lastly, these software solutions offer robust reporting and analytics capabilities. They provide real-time data on performance metrics, helping businesses make informed decisions and improve their operations.

Benefits of Using Manufacturing Operations Management Software

Using manufacturing operations management software comes with a plethora of benefits:

- Improved Efficiency: These software solutions improve efficiency by automating various tasks, reducing the likelihood of errors, and streamlining operations.

- Enhanced Productivity: They enhance productivity by ensuring that all tasks are scheduled and tracked accurately. This way, businesses can ensure that no time is wasted and every resource is utilized optimally.

- Reduced Waste: By maintaining optimal inventory levels and ensuring quality control, these software solutions significantly reduce waste.

Implementing Manufacturing Operations Software for Shop Floor Management

The utilization of such software presents numerous advantages that can streamline operations and maximize efficiency. It is imperative for businesses to carefully choose the appropriate software that aligns with their specific needs and objectives. By selecting software that caters to scalability and future growth prospects, companies can ensure long-term success. The integration of this technology into shop floor management processes can lead to a significant boost in productivity and output quality. Furthermore, the implementation of manufacturing operations software enables real-time monitoring and data analysis, facilitating informed decision-making.

PFM a Game-Changing Operations Management Software offered by LillyWorks

This innovative solution revolutionizes production scheduling by providing answers to essential questions faced by manufacturers:

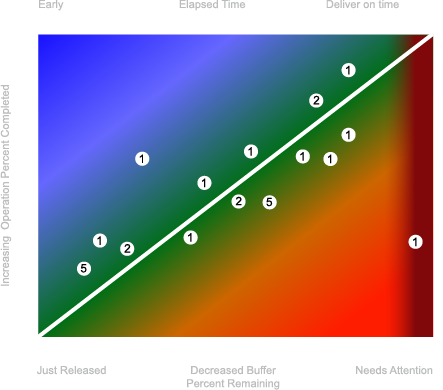

- Real-time job tracking: Easily locate and monitor the progress of your jobs to ensure efficient workflow.

- Optimal work prioritization: Identify the most critical job or work order to focus on, considering plant-wide or specific workcenter/machine/person requirements.

- Accurate delivery estimation: With insights into plant capacity and current/future load, determine precisely when your customers can expect their orders.

Say goodbye to ineffective spreadsheets, whiteboards, and traditional ERP/Advanced Planning and Scheduling (APS) tools. Embrace Protected Flow Manufacturing and experience remarkable improvements in your operations management.

Conclusion

In conclusion, manufacturing operations management software is an invaluable tool for any manufacturing business. It not only streamlines operations but also enhances productivity, improves efficiency, and reduces waste. By choosing the right software, businesses can transform their operations and achieve their business objectives more efficiently. Contact us today to learn more about how PFM by LillyWorks can help your business thrive in today’s highly competitive manufacturing landscape.