In today’s fast-paced manufacturing world, efficiency and productivity are key. The advent of new technologies and methodologies has made it possible to significantly enhance the sub assembly manufacturing process. One such methodology is Protected Flow Manufacturing. In this blog post, we will delve into what sub assembly manufacturing is, the role of shop floor scheduling, how to improve operational efficiency, the power of scheduling software, and the game-changing impact of protected flow manufacturing.

What is Sub Assembly Manufacturing?

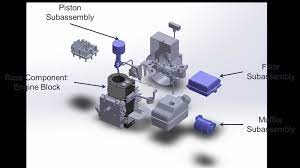

Sub assembly manufacturing is a process where individual parts are assembled to form a component, which is then used in the production of a final product. This method offers several benefits such as improved product quality, cost savings, and increased production speed. For example, in the automotive industry, engines, transmissions, and other key components are created as sub assemblies before being installed in the final vehicle.

The Role of Shop Floor Scheduling in Sub Assembly Manufacturing

Shop floor scheduling plays a crucial role in sub assembly manufacturing. It involves planning and controlling the production process from start to finish, ensuring that resources are used efficiently and deadlines are met. Effective shop floor scheduling can streamline operations, reduce waste, and increase productivity. For instance, a well-planned schedule can help avoid bottlenecks in production, ensuring that each sub assembly is completed on time and in the correct sequence.

Improving Operational Efficiency in Manufacturing

Operational efficiency in manufacturing is all about producing goods in the most cost-effective manner while maintaining high quality. It’s a balance between speed, cost, and quality. There are several strategies to boost operational efficiency in manufacturing. These include implementing lean manufacturing practices, using automation and advanced machinery, and improving worker skills through training. Improved operational efficiency not only leads to cost savings but also increases production speed and enhances product quality, which ultimately results in higher customer satisfaction.

The Power of Scheduling Software for Manufacturing

Scheduling software for manufacturing is a powerful tool that can automate and optimize the production process. It allows managers to plan and monitor production schedules, track inventory levels, and manage resources efficiently. By implementing scheduling software, manufacturers can reduce manual errors, save time, and improve productivity. For instance, a scheduling software can automatically adjust production schedules based on changes in demand or disruptions in supply, ensuring that the manufacturing process runs smoothly.

A Game Changer for Sub Assembly Manufacturing

Protected Flow Manufacturing is an innovative solution that aims to streamline the manufacturing process by prioritizing tasks based on their impact on the overall production schedule. Unlike traditional methods, which often focus on maximizing machine utilization, Protected Flow Manufacturing focuses on delivering products on time by prioritizing the jobs that can least afford to wait. This approach reduces lead times, minimizes work-in-progress inventory, and enhances overall operational efficiency. For example, a company using Protected Flow Manufacturing may prioritize a task that is due later but has significantly more work remaining over a task that utilizes that’s due sooner, focusing less on utilizing a machine to it’s maximum capacity in that moment and protecting your commitment to your customer by prioritizing on-time delivery.

Conclusion

In conclusion, the future of sub assembly manufacturing lies in leveraging advanced methodologies like Protected Flow Manufacturing and tools like scheduling software. These technologies not only enhance operational efficiency but also improve product quality and customer satisfaction. As the manufacturing industry continues to evolve, companies that embrace these changes and invest in these technologies will be well-positioned to stay ahead of the competition. Set up a demo today to see how Protected Flow Manufacturing can revolutionize your sub assembly manufacturing process. Let’s embrace the future of manufacturing together!