It’s time to rethink managing production regarding Material Planning. Traditional MRP (Material Requirements Planning) is embedded in every ERP system today as the material planning module. It was designed and developed in the 1960’s and ’70’s when North America was making refrigerators and stereos. But hasn’t changed much, if at all, since then.

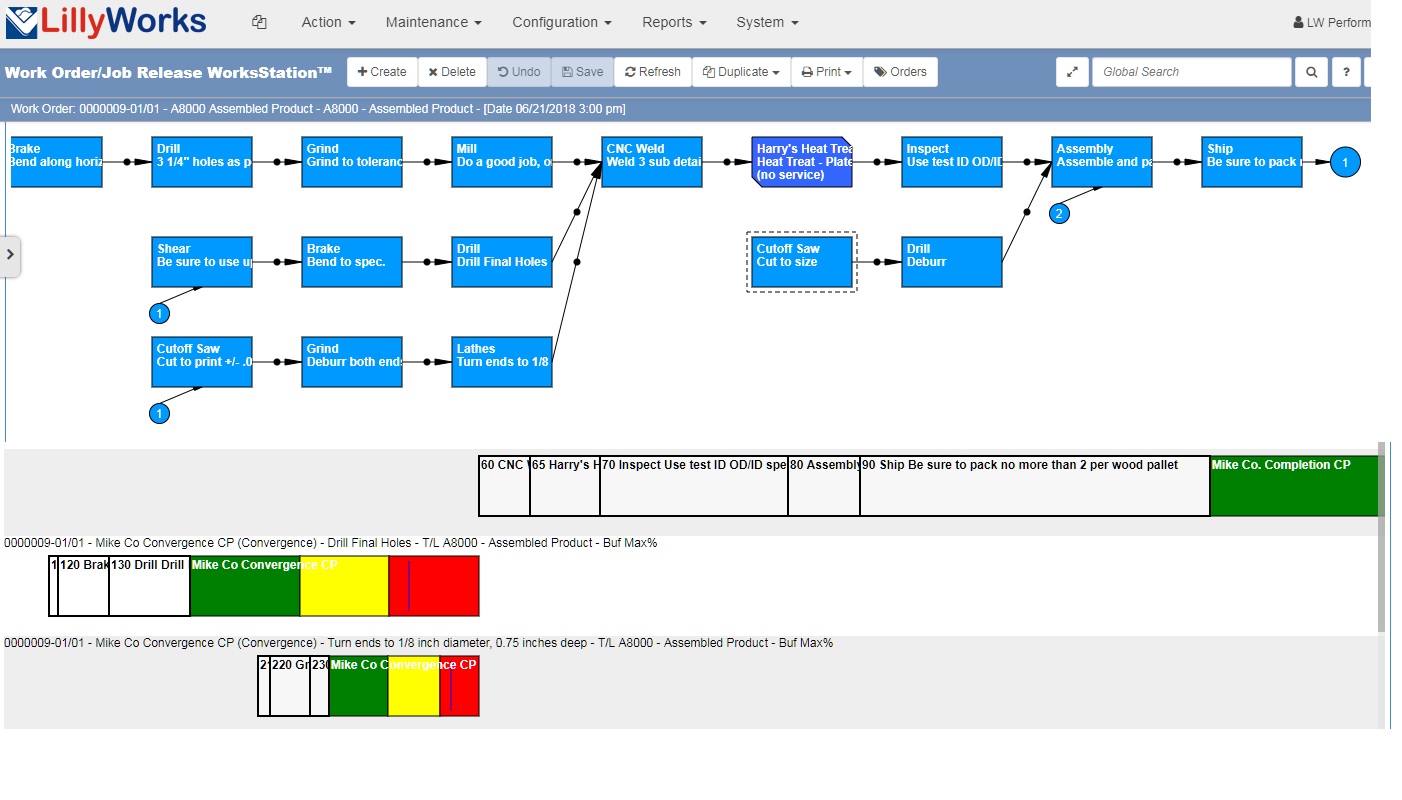

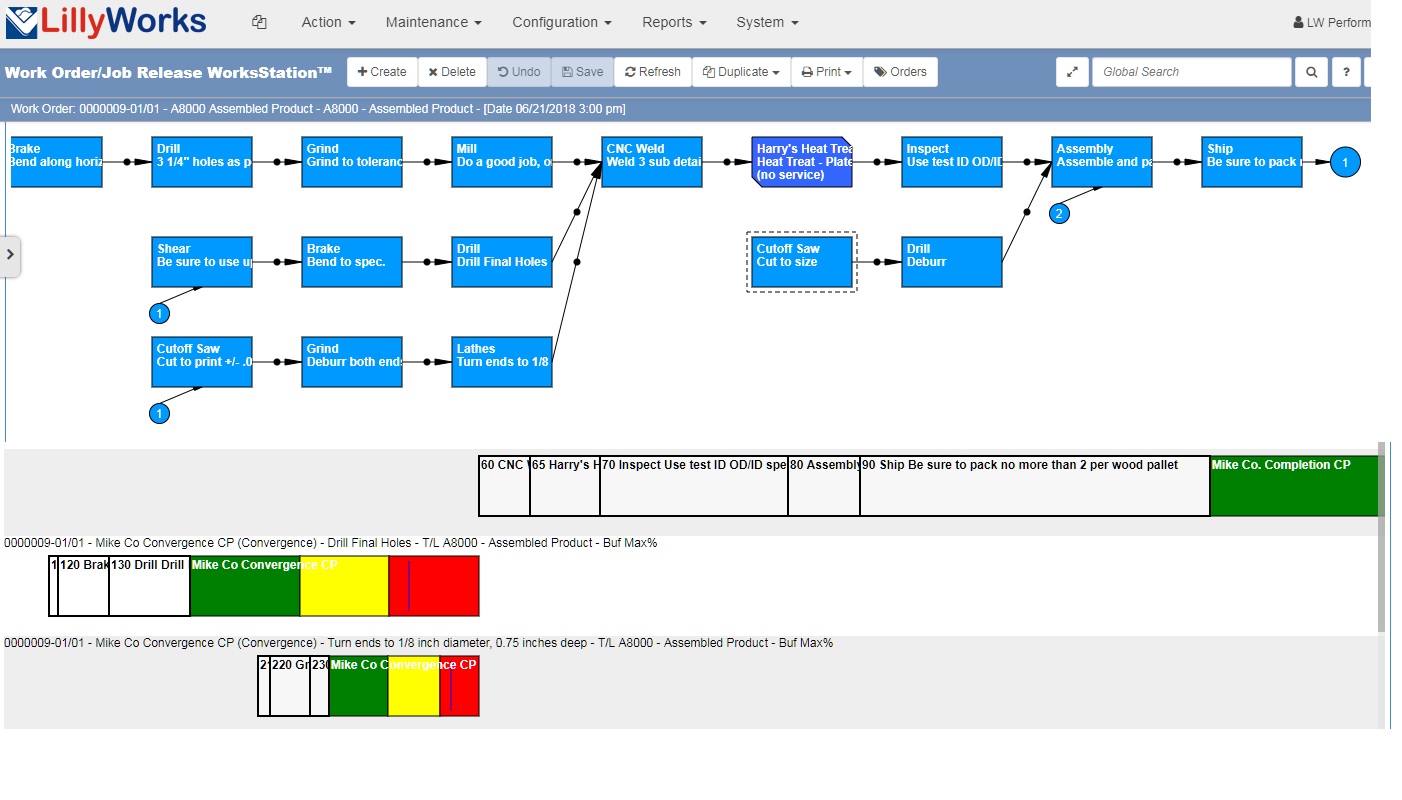

In Part 2 of this webinar series on Material Planning, we’ll explain some of the pitfalls of traditional MRP, how today’s custom, hi-mix manufacturers typically struggle, and how we can fix it with a new, better approach. This new approach builds on Part 1 showing how Material Planning and the dependencies of material and/or subassemblies is critical to improving and maintaining high levels of On-time delivery and availability of materials without having to produce or carry too much.

In this webinar, you’ll learn:

— How Make-to-Order manufacturers manage dependencies of both make-to-order and make- to-stock subassemblies to gain advantages in reducing leadtimes.

— You’ll learn a new method that ensures that you’ll always have “enough” of any item, without having “too much”.

–You’ll understand how you can prioritize both Make-to-Order and Make-to-Stock workorders together so you’re always confident that you’re working on the right one.